Katoloso ea Rack ea Gear ea Heke e Thellang ea Boima bo Holimo CNC M1, M1.5, M2, M2.5, M3

Indasteri ea Kopo

1. Liparamente tsa Rake ea Lisebelisoa

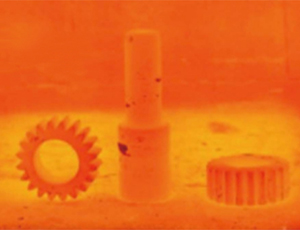

1. Thepa: Tšepe ea carbon, tšepe e sa ruseng, motsoako oa aluminium, polasetiki, koporo, jj.

2. Mojule: M1, M1.5, M2, M3, M4, M5, M6, M7, M8 jj.

3. Sekhutlo sa kgatello: 20°.

4. Kalafo ea bokaholimo: E koahetsoeng ka zinki, e koahetsoeng ka nikeli, e ntšo, e nang le carburizing, e thatafatsang le e futhumatsang, e nang le nitriding, e nang le maqhubu a phahameng, jj.

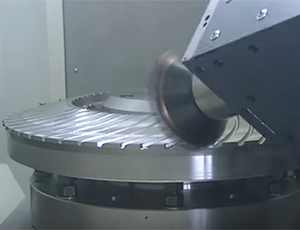

5. Mechini ea Tlhahiso: Sesebelisoa sa ho shaper, mochini oa hob, CNC lathe, mochini oa ho sila, mochini oa ho cheka, grinder jj.

6. Phekolo ea mocheso le ho tima carburing.

2. Rake ea Lisebelisoa ka har'a Sistimi ea Gantry

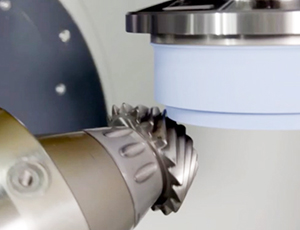

Sistimi ea gantry, rack ea gear, e tsejoang hape e lesistimi ea rack le pinion, ke actuator e otlolohileng e nang le gear e otlolohileng (rack) le gear e chitja (pinion). Ha pinion e potoloha, e khanna rack hore e tsamaee ka tatellano. Mokhoa ona o atisa ho sebelisoa bakeng sa motsamao o otlolohileng o nepahetseng le o ka phetoa-phetoang, e leng se etsang hore o lokele lits'ebetso litsamaisong tsa gantry.

Likarolo tsa Gear Rack ho Gantry Systems:

1、Motsamao o Mola:

Mosebetsi o ka sehloohong oa rack ea gear tsamaisong ea gantry ke ho fetola motsamao o potolohang oa pinion hore e be motsamao o otlolohileng oa rack. Sena se bohlokoa bakeng sa ho tsamaisa gantry tseleng e otlolohileng./

2、Ho nepahala le ho nepahala ho hoholo:

Liraka tsa li-gear li etselitsoe ho fana ka ho nepahala le ho nepahala ho hoholo, e leng habohlokoa bakeng sa mesebetsi e hlokang ho beoa hantle le ho phetoa, joalo ka ho sebetsa ka CNC, khatiso ea 3D, le mela ea kopano e iketsang.

3、Bokgoni ba ho Jara:

Liraka tsa li-gear li ka jara meroalo e meholo, e leng se etsang hore li lokele litsamaiso tsa li-gantry tse boima tse sebelisoang lits'ebetsong tsa indasteri.

4、Ho Tšoarella le Matla:

Li-rack tsa gear li entsoe ka thepa e matla joalo ka tšepe kapa li-alloy tse thatafalitsoeng, li tšoarella ebile li khona ho mamella maemo a thata a ts'ebetso, ho kenyeletsoa le meroalo e phahameng le ts'ebetso e tsoelang pele.

5、Ho se tsitse ho tlase:

Liraka tsa li-gear tsa boleng bo holimo li entsoe ka mokhoa oa ho fokotsa ho thiba ha li-gear (motsamao o monyane o ka bang teng lipakeng tsa li-gear), e leng se ntlafatsang ho nepahala le botsitso ba sistimi.

6、Ho khoneha ho hola:

Liraka tsa lisebelisoa li ka hlahisoa ka bolelele bo fapaneng 'me li ka kopanngoa ho tloha qalong ho ea qetellong ho etsa maeto a malelele bakeng sa sistimi ea gantry.

7、Lebelo le Bokgoni:

Mekhoa ea liraka tsa li-gear e ka sebetsa ka lebelo le phahameng 'me ea fana ka phetiso e sebetsang hantle ea motlakase, e leng se etsang hore e be e loketseng lits'ebetso tse fetohang moo lebelo le karabelo li leng bohlokoa.

8、Tlhokomelo le Setlolo:

Tlhokomelo e nepahetseng le ho tlotsa li-rack tsa li-gear hoa hlokahala ho netefatsa ts'ebetso e boreleli le ho lelefatsa bophelo ba likarolo.

9、Kopanyo le Mekhoa e Meng:

Liraka tsa lisebelisoa li ka kopanngoa habonolo le likarolo tse ling tsa mechini tse kang litataiso tse otlolohileng, li-motor tsa servo, le li-encoder ho theha sistimi e felletseng le e sebetsang hantle ea gantry.

10、Ho iketsetsa lintho ka mokhoa o ikhethileng:

Liraka tsa lisebelisoa li ka etsoa ka mokhoa o ikhethileng ho latela bophahamo, bolelele le thepa ho fihlela litlhoko tse itseng tsa ts'ebeliso.

Ka kakaretso, liraka tsa li-gear ke karolo ea bohlokoa litsamaisong tsa gantry, li fana ka motsamao o tšepahalang, o nepahetseng le o sebetsang hantle oa mola bakeng sa mefuta e mengata ea lits'ebetso tsa indasteri.

3. Kopano ea Katoloso ea Rake ea Gear

Ho netefatsa kopano e boreleli ea raka e hokahanyang, ho khothaletsoa ho eketsa halofo ea leino pheletsong ka 'ngoe ea raka e tloaelehileng. Sena se nolofatsa khokahano ea raka e latelang ka ho lumella meno a eona a halofo ho hokela menong a felletseng. Setšoantšo se ka tlase se bontša khokahano ea likariki tse peli le kamoo tekanyo ea leino e laolang boemo ba bophahamo ka nepo.

Ha o kopanya li-racks tsa helical, ho ka sebelisoa li-gauge tsa meno tse fapaneng ho fihlela khokahano e nepahetseng.

1. Ha o hokela raka, ho kgothaletswa ho notlela masoba mahlakoreng ka bobedi a raka pele, ebe o notlela masoba ka tatellano ho ya ka motheo. Sebedisa tekanyo ya meno nakong ya kopano ho kopanya ka nepo le ka botlalo boemo ba ho hlaba ha raka.

2. Qetellong, tiisa dipini tsa ho beha dipeipi mahlakoreng ka bobedi a raka ho phethela kopano.

Feme ea Tlhahiso

Khamphani ea rona e na le sebaka sa tlhahiso sa limithara tse lisekoere tse 200,000, e hlomelitsoe ka lisebelisoa tsa tlhahiso le tlhahlobo tse tsoetseng pele ka ho fetisisa ho fihlela litlhoko tsa bareki. Ho phaella moo, re sa tsoa hlahisa setsi sa machining sa Gleason FT16000 sa li-axis tse hlano, e leng mochini o moholo ka ho fetisisa oa mofuta oa oona Chaena, o etselitsoeng tlhahiso ea lisebelisoa ka ho khetheha ho latela tšebelisano-'moho pakeng tsa Gleason le Holler.

- Mefuta ea Modulus: 0.5-42M

- Sehlopha sa ho nepahala: 5-10.

- Sehlopha sa 5, bolelele bo fihlang ho 1000 mm ka sengoathoana se le seng

- Sehlopha sa 6, bolelele ba sona bo fihlang ho 2000 mm ka karolo e le 'ngoe.

Re motlotlo ka ho khona ho fana ka tlhahiso e ikhethang, ho tenyetseha le ho boloka litšenyehelo ka tsela e ikhethang ho bareki ba rona ba nang le litlhoko tse tlase. U ka itšetleha ka rona hore re fane ka lihlahisoa tsa boleng bo holimo ka linako tsohle ho latela litlhoko tsa hau tse nepahetseng.

Phallo ea Tlhahiso

Lisebelisoa tse so ntlafatsoe

Ho Seha ka Bohloko

Ho reteleha

Ho tima le ho nolofatsa

Ho Sila Li-Gear

Kalafo ea Mocheso

Ho Sila ha Lisebelisoa

Teko

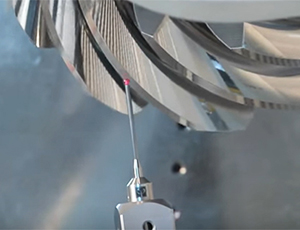

Tlhahlobo

Re tsetetse lisebelisoa tsa morao-rao tsa liteko tsa sejoale-joale, ho kenyeletsoa mechini ea ho lekanya ea Brown & Sharpe, Mochini oa ho lekanya oa Hexagon oa Swedish, Mochini o Kopaneng oa German Mar High Precision Roughness Contour, Mochini oa ho lekanya oa Zeiss Coordinate oa Jeremane, Sesebelisoa sa ho lekanya sa Gear sa Klingberg sa Jeremane, Sesebelisoa sa ho lekanya sa Profile sa Jeremane le liteko tsa roughness tsa Japane jj. Litsebi tsa rona tse nang le boiphihlelo li sebelisa theknoloji ena ho etsa litlhahlobo tse nepahetseng le ho netefatsa hore sehlahisoa se seng le se seng se tsoang fekthering ea rona se fihlela maemo a holimo a boleng le ho nepahala. Re ikemiselitse ho feta litebello tsa hau nako le nako.

Liphutheloana